1-866-2-AUTOM8

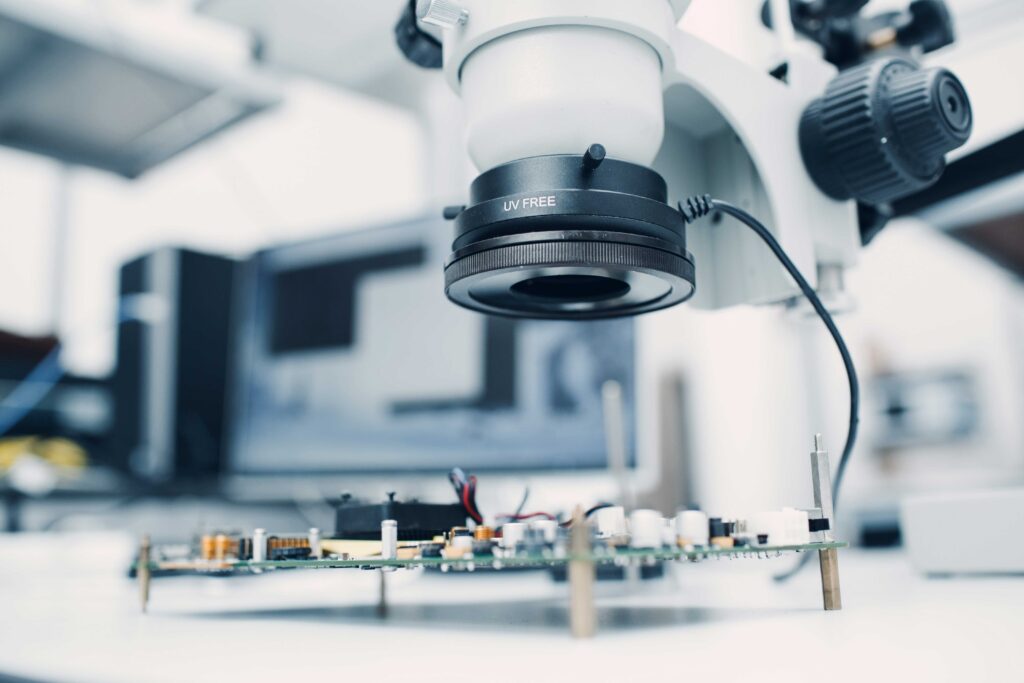

Machine Vision Inspection

Automate & Optimize

Our Machine Vision Services

Revolutionizing Automation with Visual Intelligence

What is Machine Vision?

Machine vision is a technology that allows machines to interpret visual information from the world, much like human vision but with greater precision and consistency. It involves using cameras, image processing software, and algorithms to capture and analyze visual data. This technology can inspect products for defects, guide robotic arms, sort items, and more. In industrial settings, machine vision enhances automation by providing real-time data and enabling precise control over manufacturing processes.

- Applications: Quality control, quality assurance, inline inspection, customer service retention, and process inspection.

- Services: Setup, testing, and programming of Omron, Cognex, and Keyence cameras and related software.

Ensuring Superior Product Standards

Machine Vision for Quality Control

Continuous Monitoring for Optimal Quality

Machine Vision for Inline Inspection

Precision Handling of Mixed Items

Bin Picking Automation

Enhancing Precision and Safety in Operations

Machine Tending

Is Machine Vision Right for You?

Integrating machine vision inspection systems into your operations offers numerous benefits. By streamlining processes through automation with machine vision, you achieve increased efficiency and enhanced accuracy in defect detection and item handling. Improved safety is another key advantage, as machine vision reduces the risks associated with manual tasks. Big Industries leverages the latest in vision automation technology to provide tailored solutions for your manufacturing and warehousing needs, ensuring seamless integration and optimal performance.

Contact us to learn more about how our vision automation solutions can improve your operations.